|

| March 28, 2023 | Volume 19 Issue 12 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Metasurfaces could enable flatter TV screens with 10x resolution

A team across three universities in Australia and the UK has developed new "metasurface" technology that may one day offer significant benefits over current LCD and LED tech, including incredible thinness, much greater resolution, and less energy consumption.

The metasurfaces are 100 times thinner than liquid crystal cells, offer a tenfold greater resolution, and could consume less energy. The group's findings were published Feb. 23, 2023, in Light: Science & Applications.

Metamaterials are synthetic structures composed of building blocks that are smaller than the wavelengths of light they are designed to manipulate.

Today's screen display market offers a large range of choices, each with its pros and cons. However, factors including production costs, lifespan, and energy consumption have kept LCD technology the most dominant and popular technology for screens such as TV sets and monitors.

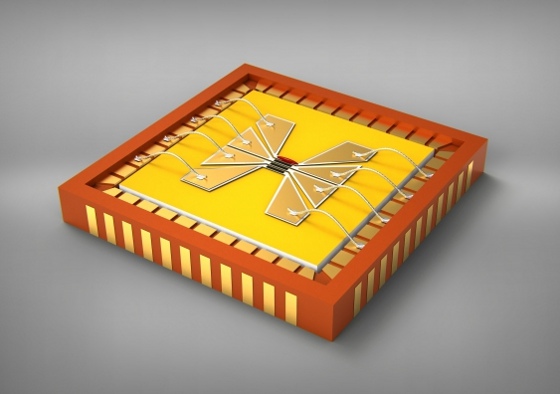

Newly designed metasurfaces are thinner than liquid crystal cells, offer a greater resolution, and could consume less energy for display technology. [Image credit: Andrey Miroshnichenko/UNSW Canberra]

Liquid crystal cells are responsible for switching the transmitted light on and off and are constantly lit by a backlight, with polarizing filters in the front and behind the pixels, forming a cross-polarized setup. They determine the dimension of pixels, the resolution, and play a significant role in managing the device's power consumption.

The newly engineered metasurface cells, which have tunability and extraordinary light-scattering properties, would replace the liquid crystal layer and would not require the polarizers, which are responsible for half of the wasted light intensity and energy use in displays.

"Our pixels are made of silicon, which offers a long life span in contrast with organic materials required for other existing alternatives. Moreover, silicon is widely available, CMOS*-compatible with mature technology, and cheap to produce," said Professor Andrey Miroshnichenko, a lead researcher in the Nanophotonics team at UNSW Canberra. "We hope this development could generate a frontier technology in new flat screen displays, which had a global market value of about $117 billion in 2020."

Building a large-scale prototype

The next phase of research will be building a large-scale prototype and generating images, which is hoped to be achieved within the next five years. Once the prototype has successfully generated high-definition images, it is expected the technology will be integrated into flat screens and available to the public within the next 10 years.

Professor Dragomir Neshev, director of the ARC Center for Excellence in Transformative Meta-Optical Systems (TMOS) and an ANU professor in Physics, said the capability of conventional flat screen displays has reached its peak and is unlikely to improve significantly in the future due to multiple limitations.

"Today there is a quest for fully solid-state flat display technology with a high resolution and fast refresh rate. We have designed and developed metasurface pixels that can be ideal for the next-generation display," Neshev said. "Unlike liquid crystals, our pixels do not require polarized lights for functioning, which will halve screens' energy consumption."

Khosro Zangeneh Kamali, a PhD scholar at ANU and the first author of the study, said metasurfaces are proven to exhibit extraordinary optical behavior. "Inventing an effective way to control metasurfaces is still a subject of heavy research. We have proposed electrically tunable silicon nanostructures, which is a versatile platform for programmable metasurfaces," Zangeneh Kamali said.

"There is significant room for further improvements by employing artificial intelligence and machine learning techniques to design and realize even smaller, thinner, and more efficient metasurface displays," added Dr. Lei Xu, a team member from Nottingham Trent University.

"We have paved the way to break a technology barrier by replacing the liquid crystal layer in current displays with a metasurface, enabling us to make affordable flat screens liquid crystal-free," said lead researcher Mohsen Rahmani, professor of Engineering at Nottingham Trent University's School of Science and Technology and a Royal Society Wolfson Fellow. "The most important metrics of flat panel displays are pixel size and resolution, weight, and power consumption. We have addressed each of these with our meta-display concept.

"Most importantly, our new technology can lead to a huge reduction of energy consumption," added Rahmani. "This is excellent news, given the number of monitors and TV sets being used in households and businesses every single day. We believe it is time for LCD and LED displays to be phased out in the same way as former cathode ray tube (CRT) TVs over the past 10 to 20 years."

EDITOR'S NOTE: Metasurfaces have been used to make a camera the size of a grain of salt. See Designfax Feb. 1, 2022, article here.

* CMOS stands for Complementary Metal-Oxide-Semiconductor and is a technology used for constructing integrated circuit (IC) chips, including microprocessors, microcontrollers, memory chips, and other digital logic circuits. CMOS technology is also used for analog circuits such as image sensors (CMOS sensors), data converters, RF circuits (RF CMOS), and highly integrated transceivers for many types of communication.

Source: UNSW Canberra

Published March 2023

Rate this article

View our terms of use and privacy policy